About Production

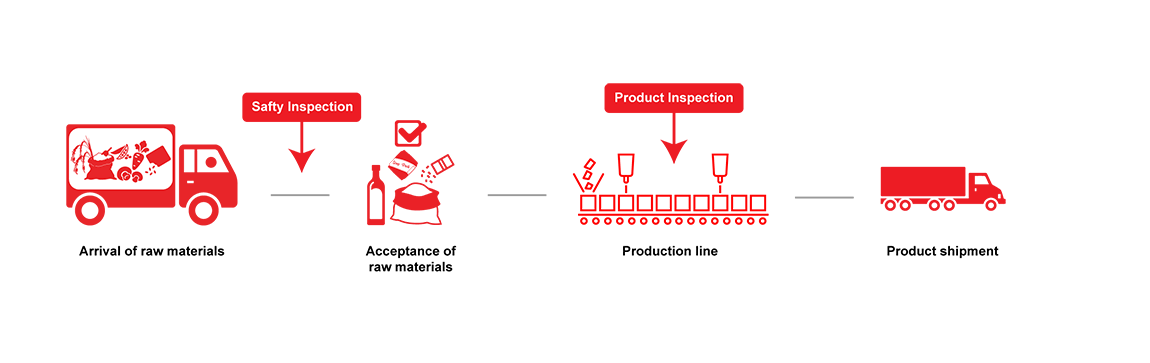

Safety is guaranteed through state-of-the-art facilities and human checks

At each Sanyo Foods factory, highly automated manufacturing lines are operated under total computer control. A variety of inspection and checking equipment is installed at each part of the production process to guarantee safety.

At the same time, employees are fully utilized to supplement the performance of our machines. Products are sampled multiple times a day for quality assurance. The contents and packing are also overseen by our well-trained employees. These advanced automated inspections coupled with human testing are our way of ensuring that consumers can rely on the safety and excellence of our products.

Product Inspection

Using X-rays and other technology on the production line, we are able to weigh and inspect products for metal and foreign objects. Workers also conduct visual inspections. Moreover, we undertake sensory testing and analysis to ensure safety and quality.

Traceability

Through the use of expirations dates and manufacturer plant ID codes, we can identify which factory our raw materials came from and when they were produced.